Introduction: Australia’s Role in the Global EV Battery Revolution

EV Battery Manufacturers in Australia are transforming transportation globally, and battery technology lies at the core of this revolution. As nations transition toward carbon-neutral mobility, demand for high-performance, sustainable, and affordable EV batteries continues to skyrocket.

Australia, traditionally known for its vast mineral resources — including lithium, nickel, cobalt, and graphite — is evolving from being just a raw-material exporter into an emerging hub for advanced EV battery manufacturing and innovation.

In this article, we explore the leading EV battery manufacturers in Australia in 2025, their technological contributions, and how government policies and private investments are shaping the country’s battery future.

Overview of Australia’s EV Battery Industry

As of 2025, Australia’s battery industry is worth over AUD 4 billion, growing at an annual rate of nearly 30%. The sector includes players in:

-

Battery cell manufacturing (small and medium scale)

-

Cathode and anode material processing

-

Battery recycling and energy storage systems

-

Research, development, and testing facilities

The government’s Future Made in Australia Act and National Battery Strategy have accelerated funding for pilot plants, research centers, and manufacturing projects.

Australia’s strength lies in upstream and midstream capabilities — refining, processing, and developing materials like lithium carbonate, graphite anodes, and cathode precursors. Full-scale gigafactory operations are still in progress, but the groundwork is solid.

Why Australia Is an EV Battery Powerhouse in the Making

| Factor | Impact on Battery Industry |

|---|---|

| Abundant minerals | Largest lithium producer; rich in nickel, cobalt, graphite. |

| Stable regulatory environment | Encourages clean energy investments and sustainable mining. |

| Government incentives | ARENA and Clean Energy Finance Corporation fund battery projects. |

| R&D expertise | Strong collaboration between CSIRO, universities, and industry. |

| Strategic trade location | Close to key Asian EV markets (Japan, Korea, China). |

These factors make Australia an attractive destination for battery technology partnerships, investment, and sustainable EV supply chains.

Top EV Battery Manufacturers in Australia (2025)

Novonix

-

Headquarters: Brisbane, Queensland

-

Founded: 2013

-

Specialization: Synthetic graphite, anode materials, and battery testing solutions

Overview:

Novonix is a flagship name in Australia’s battery ecosystem. The company develops synthetic graphite anode materials used in lithium-ion batteries and is one of the few Western suppliers capable of large-scale production outside of China.

It also offers battery testing equipment and performance analytics used by global manufacturers like Panasonic and Samsung SDI.

Why It Matters:

Novonix bridges the gap between R&D and commercialization, providing both materials and testing expertise crucial for large-scale EV production.

Talga Group

-

Headquarters: Perth, Western Australia

-

Founded: 2010

-

Specialization: Graphite anode materials and sustainable battery components

Overview:

Talga Group focuses on graphite anode production using sustainable processes. Its innovative Talnode® product family delivers high energy density and improved cycle life for EV batteries.

In 2025, Talga expanded its recycling operations, introducing Talnode-R, a recycled anode material made from battery waste.

Why It Matters:

Talga’s integration of sustainable mining and recycled materials supports Australia’s net-zero goals and positions it as a global leader in low-carbon battery production.

VSPC (Very Smart Particle Company)

-

Headquarters: Brisbane, Queensland

-

Parent Company: Lithium Australia NL

-

Specialization: Cathode powder manufacturing

Overview:

VSPC develops cathode materials essential for lithium-ion battery performance. Backed by ARENA funding, the company operates a demonstration facility producing advanced cathode powders such as LFP (Lithium Iron Phosphate).

Why It Matters:

By producing cathode powders domestically, VSPC reduces dependence on overseas suppliers and strengthens Australia’s midstream manufacturing capabilities.

Syrah Resources

-

Headquarters: Melbourne, Victoria

-

Founded: 2011

-

Specialization: Natural graphite production and processing

Overview:

Syrah Resources operates the Balama Graphite Project and is one of the world’s largest suppliers of natural graphite. In 2025, it expanded into downstream processing, producing anode-grade graphite for EV batteries.

Why It Matters:

As the demand for graphite anodes grows, Syrah’s vertically integrated operations secure Australia’s position in global graphite supply chains.

Recharge Industries

-

Headquarters: Geelong, Victoria

-

Founded: 2021

-

Specialization: Lithium-ion cell manufacturing (Gigafactory)

Overview:

Recharge Industries is leading efforts to establish one of Australia’s first large-scale battery gigafactories in Geelong. The project aims to produce lithium-ion cells for EVs and grid storage, using locally sourced raw materials.

Why It Matters:

Recharge Industries represents Australia’s ambition to scale up from materials processing to full battery production, reducing reliance on imports.

Energy Renaissance

-

Headquarters: Tomago, New South Wales

-

Founded: 2015

-

Specialization: Lithium-ion battery manufacturing (LFP technology)

Overview:

Energy Renaissance manufactures safe, efficient LFP batteries suitable for both EVs and stationary storage. The company’s “Renaissance One” facility is one of the few operational battery plants in Australia.

Why It Matters:

Its localized production supports Australia’s clean energy transition and demonstrates commercial viability for domestic EV battery manufacturing.

Redflow (Stationary Battery Specialist)

-

Headquarters: Brisbane, Queensland

-

Specialization: Zinc-bromine flow batteries

Overview:

While not focused on EVs, Redflow contributes to Australia’s broader energy storage ecosystem. Its flow batteries are used in grid and off-grid renewable storage, supporting EV charging infrastructure.

Why It Matters:

Energy storage companies like Redflow help stabilize renewable energy grids, indirectly supporting EV adoption and battery reuse strategies.

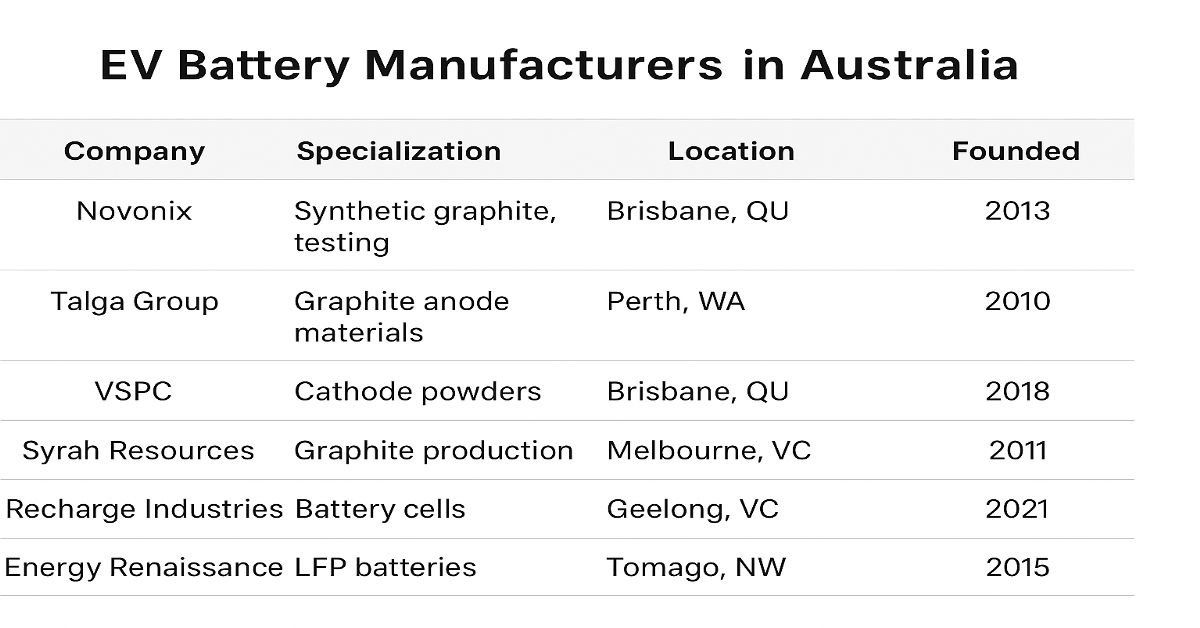

Comparison Table — Australia’s Top EV Battery Manufacturers (2025)

| Company | Specialization | Key Strength | Founded | Location |

|---|---|---|---|---|

| Novonix | Synthetic graphite & testing | Advanced anode materials & lab systems | 2013 | Brisbane, QLD |

| Talga Group | Graphite anode materials | Sustainable & recycled products | 2010 | Perth, WA |

| VSPC | Cathode powders (LFP, NMC) | Government-funded R&D | 2018 | Brisbane, QLD |

| Syrah Resources | Graphite mining & processing | Vertically integrated graphite chain | 2011 | Melbourne, VIC |

| Recharge Industries | Lithium-ion cell manufacturing | First major gigafactory | 2021 | Geelong, VIC |

| Energy Renaissance | LFP battery manufacturing | Locally built safe batteries | 2015 | Tomago, NSW |

| Redflow | Flow batteries | Energy storage integration | 2005 | Brisbane, QLD |

Government Support and Policy Initiatives

Australia’s federal and state governments are heavily investing in building a domestic battery value chain. Key programs include:

| Program/Agency | Type of Support | Example Project |

|---|---|---|

| ARENA (Australian Renewable Energy Agency) | Grants for R&D and commercialization | $30M to VSPC for cathode powder demo facility |

| Clean Energy Finance Corporation (CEFC) | Low-interest loans and equity investments | Supported Energy Renaissance’s LFP facility |

| Future Made in Australia Act | National manufacturing funding | Backing Recharge Industries’ gigafactory |

| CSIRO Battery Research Program | R&D and industry partnerships | Innovations in recycling and next-gen cells |

These programs help bridge the gap between innovation and commercialization, creating local jobs and reducing dependency on imports from Asia.

Challenges Facing Australian Battery Manufacturers

Despite promising growth, several challenges persist:

-

High capital requirements: Gigafactories need billions in investment and stable long-term demand.

-

Limited domestic EV market: While growing, Australia’s EV adoption lags behind Europe and China.

-

Skilled workforce shortage: Specialized engineers and chemists are in high demand.

-

Global competition: Asian giants like CATL, LG Energy Solution, and Panasonic dominate cell production.

-

Supply chain logistics: Transporting processed materials between mining regions and coastal hubs adds cost.

Future Outlook: The Road Ahead (2025–2030)

| Timeline | Expected Development |

|---|---|

| 2025–2026 | Expansion of Recharge Industries’ gigafactory; pilot-scale cathode/anode plants operational. |

| 2026–2027 | New lithium refining and graphite processing projects commence. |

| 2028–2030 | Australia could produce full EV battery packs domestically and export components regionally. |

By 2030, Australia aims to be among the top 10 global suppliers of advanced battery materials, with a strong domestic ecosystem covering mining → refining → manufacturing → recycling.

Battery Recycling and Sustainability Initiatives

Battery recycling is an emerging pillar of the Australian EV ecosystem. Companies like Envirostream (a Lithium Australia subsidiary) and Talga are developing circular supply chains for lithium, nickel, and cobalt recovery.

Why Recycling Matters

-

Reduces dependency on imported raw materials

-

Lowers environmental impact and carbon footprint

-

Enables re-use of valuable metals from end-of-life EV batteries

Australia’s National Battery Stewardship Scheme encourages responsible collection, sorting, and re-manufacturing of used batteries — an essential step toward a sustainable EV future.

Research and Innovation: Australia’s R&D Advantage

Australia’s scientific community plays a vital role in shaping its battery industry. Organizations like CSIRO, Monash University, and University of Queensland are pioneering in areas like:

-

Solid-state battery research

-

High-capacity lithium-sulfur prototypes

-

Recyclable electrode materials

-

Advanced battery testing facilities

These collaborations between academia and industry help turn lab-scale innovation into commercial products.

Impact on Australia’s Economy and Job Market

The EV battery sector is projected to create more than 30,000 new jobs by 2030.

Employment spans across:

-

Mining and refining

-

Manufacturing and logistics

-

Research and design

-

Recycling and sustainability

Furthermore, battery exports could contribute over AUD 7 billion annually by 2035, diversifying Australia’s economy beyond fossil fuels.

Summary Table — Australia’s Battery Supply Chain Segments

| Segment | Leading Companies | Key Activities |

|---|---|---|

| Mining & Raw Materials | Pilbara Minerals, IGO, Syrah Resources | Lithium, Nickel, Graphite extraction |

| Processing & Refining | Talga Group, VSPC, Novonix | Anode/Cathode material production |

| Cell Manufacturing | Recharge Industries, Energy Renaissance | Lithium-ion cell assembly |

| Battery Recycling | Envirostream, Talga | Metal recovery, circular supply |

| Research & Development | CSIRO, Monash University | Battery chemistry, performance testing |

Expert Opinion: How Close Is Australia to Battery Independence?

“Australia’s strength lies in its resources and innovation. The challenge is scaling these innovations to compete globally. With steady policy support, local companies can become vital players in the Asia-Pacific battery supply chain.”

— Dr. Michael Reynolds, Battery Materials Scientist, CSIRO

Conclusion: Powering a Sustainable Future

The EV battery manufacturing industry in Australia is on an exciting growth trajectory.

From Novonix’s synthetic graphite breakthroughs to Recharge Industries’ gigafactory ambitions, Australia is rapidly building the capabilities needed to compete in the global clean energy race.

Government incentives, private investments, and strong R&D partnerships are driving this transformation — making Australia not just a resource exporter but a battery technology innovator.

As electric mobility continues to expand, Australia’s EV battery ecosystem will play a crucial role in delivering sustainable, reliable, and locally produced energy storage solutions.

1 thought on “EV Battery Manufacturers in Australia”