⚡ Introduction: Why EV Battery Recycling Matters

EV Battery Recycling Companies in Australia electric vehicle market is expanding rapidly, supported by government policies, consumer awareness, and advancements in battery technology. But as EV adoption grows, so does a pressing question: What happens to all those lithium-ion batteries once they reach the end of their life?

EV batteries, rich in valuable materials like lithium, nickel, cobalt, and manganese, pose both an opportunity and a challenge. Without proper recycling, these components can contribute to hazardous waste. Yet, when managed responsibly, they can become a renewable source of critical minerals—supporting Australia’s transition toward a sustainable circular economy.

That’s where EV battery recycling companies in Australia come into play. They’re not just solving an environmental issue—they’re building a future-proof industry.

🧠 Understanding EV Battery Recycling

The Process in a Nutshell

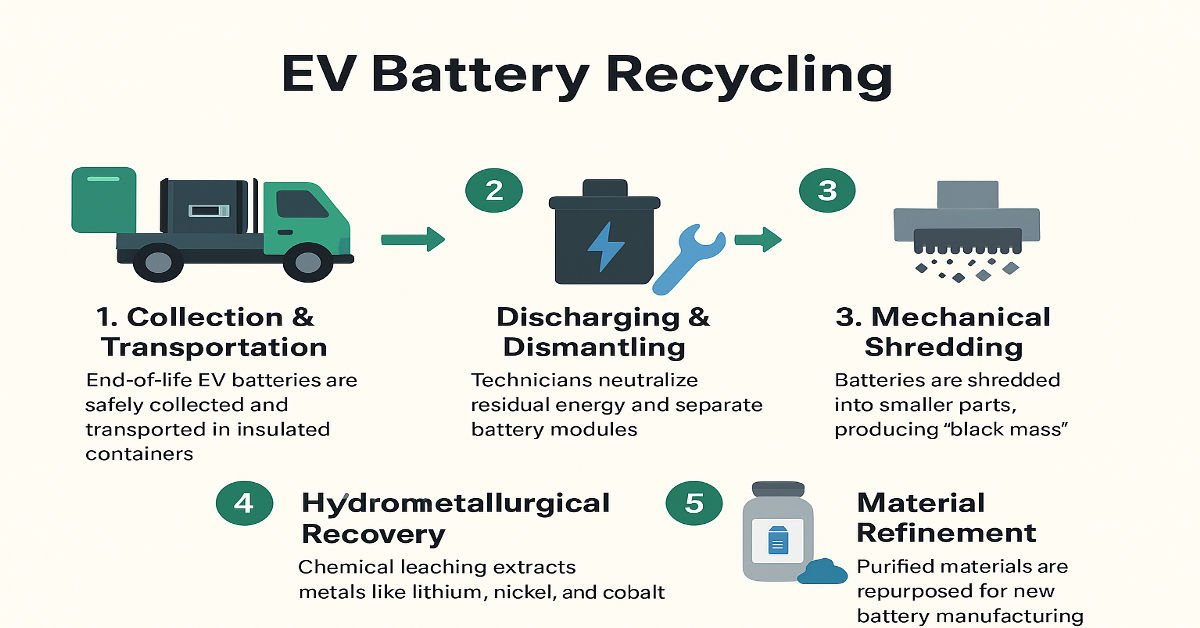

EV battery recycling isn’t simply breaking down a battery—it’s a precise, multi-stage process designed to recover up to 95% of valuable materials safely.

Stages of EV Battery Recycling

| Stage | Process | Description |

|---|---|---|

| 1 | Collection & Transportation | End-of-life EV batteries are safely collected and transported in insulated containers. |

| 2 | Discharging & Dismantling | Technicians neutralize residual energy and separate battery modules. |

| 3 | Mechanical Shredding | Batteries are shredded into smaller parts, producing “black mass.” |

| 4 | Hydrometallurgical Recovery | Chemical leaching extracts metals like lithium, nickel, and cobalt. |

| 5 | Material Refinement | Purified materials are repurposed for new battery manufacturing. |

Each company may use variations of this process, often protected by proprietary technology or research collaboration with Australian universities.

🌏 Australia’s EV Landscape and Policy Framework

Government Backing for Battery Circularity

Australia’s federal and state governments have made sustainability a cornerstone of transport policy. The Battery Stewardship Scheme (B-cycle) and grants like the Circular Economy Infrastructure Fund support the establishment of battery recycling plants nationwide.

-

B-cycle: A national initiative ensuring safe collection of used batteries.

-

Circular Economy Victoria: Provides funding for lithium-battery facilities such as the one in Campbellfield.

-

Critical Minerals Strategy 2024: Positions Australia as a regional leader in the lithium and battery value chain.

According to the Battery Stewardship Council, Australia could generate more than 30,000 tonnes of used EV batteries by 2030—a massive opportunity for recyclers.

🏭 Leading EV Battery Recycling Companies in Australia

Let’s explore the major players turning battery waste into energy resources.

1️⃣ Lithium Australia Limited (and its subsidiary Envirostream)

Overview:

Lithium Australia (ASX: LIT), through its recycling arm Envirostream, is a pioneer in large-format lithium-ion battery recycling. Headquartered in Melbourne, Envirostream recovers key materials like cobalt, nickel, manganese, and lithium from EV batteries.

Key Features:

-

Operates Australia’s first commercial EV battery recycling plant.

-

Partners with BYD Australia and other automakers for battery take-back programs.

-

Employs a hybrid mechanical-hydrometallurgical process for maximum recovery efficiency.

-

Works alongside universities to enhance battery recovery technologies.

Impact:

Envirostream’s operations help close the loop on Australia’s growing EV ecosystem, ensuring valuable minerals remain in domestic circulation.

| Metric | Value |

|---|---|

| Head Office | Melbourne, VIC |

| Processing Capacity | 3,000+ tonnes/year |

| Recovery Rate | Up to 95% metals |

| OEM Partners | BYD, LG, Tesla (research phase) |

EcoBatt (Part of Ecocycle Group)

Overview:

EcoBatt is one of the most recognized names in Australia’s battery recycling landscape. Its parent company, Ecocycle Group, manages a wide range of waste streams, including lighting and e-waste. EcoBatt’s facility in Campbellfield, Victoria, is a milestone in the country’s lithium-ion recycling capability.

Key Features:

-

Australia’s first “Battery-in-Device Shredding” (BIDS) plant.

-

Supported by the Victorian Government’s Circular Economy Fund.

-

Focus on EV battery and energy-storage system recycling.

-

Safe handling of hazardous lithium-ion cells with fire-suppression technology.

Impact:

EcoBatt’s advanced shredding and sorting system minimizes manual handling risks while achieving recovery rates exceeding 90%. The company plans to expand its recycling capacity as EV sales rise across Australia.

| Aspect | Details |

|---|---|

| Location | Campbellfield, VIC |

| Specialty | EV and embedded battery recycling |

| Annual Capacity (target) | 30,000 tonnes |

| Notable Support | Government of Victoria |

Infinitev (Battery Reuse & Recycling Innovator)

Overview:

Unlike traditional recyclers, Infinitev takes a unique approach—repurposing EV and hybrid batteries for second-life applications before they enter recycling. Based in Melbourne, Infinitev converts used battery modules into stationary storage units for homes and businesses.

Key Features:

-

Focus on battery reuse, not just recycling.

-

Reduces waste and extends product lifespan.

-

Collaborates with automotive dealerships for take-back programs.

-

Testing and certification ensure safe second-life deployment.

Impact:

Infinitev’s approach delays recycling until batteries truly reach the end of their useful life—maximizing economic and environmental value.

| Feature | Description |

|---|---|

| Approach | Reuse → Repurpose → Recycle |

| Founded | 2018 |

| Headquarters | Melbourne, VIC |

| Focus | EV & hybrid batteries, stationary energy storage |

ReSource Technology (Emerging Recycler in WA)

Overview:

Operating in Western Australia, ReSource Technology focuses on recovering critical minerals from industrial and EV batteries using hydrometallurgical methods. Their facility integrates recycling with chemical refining, a vital step to localize material recovery.

Key Features:

-

Specializes in black mass refining for battery-grade lithium.

-

Strategic location near Perth, close to mining infrastructure.

-

Developing partnerships with local EV assemblers and logistics fleets.

-

Research collaboration with Curtin University on solvent extraction technologies.

Impact:

ReSource contributes to Australia’s ambition to become a battery-mineral refining hub, complementing its vast mining resources with recycling.

🔬 The Technology Behind Recycling

The technologies driving Australian recyclers vary, but they share the same goal: maximum recovery with minimal environmental footprint.

Core Recycling Techniques

| Technology | Description | Used By |

|---|---|---|

| Mechanical Separation | Shredding and sieving separate metals and plastics. | EcoBatt, Envirostream |

| Hydrometallurgical Process | Uses chemical leaching to extract lithium, cobalt, and nickel. | ReSource, Envirostream |

| Pyrometallurgical Process | High-temperature smelting to recover metals. | Under R&D in CSIRO labs |

| Direct Recycling | Restores battery materials for immediate reuse. | University R&D Projects |

Fun Fact:

Australia’s CSIRO (Commonwealth Scientific and Industrial Research Organisation) is developing direct recycling technologies that could recover up to 98% of materials—reducing costs and energy use.

📈 Market Trends and Future Outlook

The Rising EV Battery Waste Curve

By 2035, experts estimate over 100,000 tonnes of lithium-ion batteries will require recycling each year in Australia. This growth is being accelerated by:

-

Rapid EV adoption (target: 89% of new cars electric by 2040).

-

Renewable energy storage systems reaching end-of-life.

-

International pressure for battery supply-chain transparency.

Government and Industry Collaboration

The government’s Critical Minerals Strategy 2024 encourages recycling to complement mining exports. Meanwhile, the Battery Stewardship Council and industry groups are building national recycling standards.

Table: Key Market Drivers

| Driver | Description | Effect |

|---|---|---|

| Policy Support | Circular economy grants and stewardship schemes | Encourages private investment |

| EV Sales Growth | Increased battery stock entering the market | Expands recycling feedstock |

| OEM Partnerships | EV manufacturers seek certified recyclers | Boosts long-term contracts |

| Mineral Demand | Rising global lithium/cobalt needs | Makes recycling more profitable |

🌱 Environmental & Economic Benefits

Recycling batteries provides Australia with multiple advantages beyond sustainability slogans.

-

Reduces Mining Pressure: Less demand for virgin raw materials means fewer ecological disruptions.

-

Cuts Carbon Footprint: Recycling requires significantly less energy than mining and refining new ores.

-

Creates Jobs: Recycling plants require skilled technicians, engineers, and logistics professionals.

-

Boosts Critical-Mineral Security: Keeps valuable resources within national borders.

-

Promotes Innovation: Drives investment in green technology and education.

⚙️ Challenges Facing the Industry

While the momentum is strong, recyclers face notable hurdles.

| Challenge | Explanation |

|---|---|

| Low Battery Return Volumes | EVs are still new in Australia; battery waste flow is limited. |

| Transport Regulations | Lithium batteries are hazardous and require strict logistics compliance. |

| Economic Viability | Recycling profitability depends on metal prices and processing efficiency. |

| Technological Readiness | New chemistries like LFP require specialized processes. |

| Public Awareness | Consumers often unaware of proper disposal programs. |

Solution Path:

Government incentives, OEM partnerships, and increased consumer education can address these barriers as the EV market matures.

🚗 The Role of Automakers and Partnerships

Automakers are beginning to integrate recycling into their lifecycle models.

-

BYD Australia: Partnered with Lithium Australia for safe battery take-back.

-

BMW Australia: Runs an in-house battery recycling pilot.

-

Tesla Australia: Sends end-of-life batteries to approved recyclers under global sustainability commitments.

-

Hyundai: Collaborating with local recyclers to test second-life storage projects.

These collaborations are critical for volume growth and establishing closed-loop systems.

🧩 Comparison Table: Top EV Battery Recycling Companies in Australia

| Company | Location | Focus Area | Annual Capacity | Technology | Key Partnerships |

|---|---|---|---|---|---|

| Lithium Australia (Envirostream) | Melbourne | Large EV packs | 3,000 t | Mechanical + Hydro | BYD, LG |

| EcoBatt (Ecocycle Group) | Campbellfield | All battery types | 30,000 t (target) | BIDS + Hydro | Govt of Victoria |

| Infinitev | Melbourne | Reuse & Repurpose | N/A | Testing + Refurbishment | Dealerships |

| ReSource Technology | Perth | Black mass refining | 5,000 t | Hydrometallurgy | Curtin University |

🔮 Future Outlook: Australia’s Circular Energy Vision

By 2035, Australia is expected to have a fully integrated EV battery recycling ecosystem, powered by:

-

Nationwide collection networks.

-

Standardized recycling regulations.

-

Export opportunities for refined black-mass materials.

-

Local manufacturing of next-gen battery cells using recycled feedstock.

This evolution will make Australia not just a miner of lithium, but also a leader in circular battery manufacturing.

1 thought on “EV Battery Recycling Companies in Australia: Driving the Circular Energy Future”